Henan Junmei Aluminum Industry Co., Ltd. covers a construction area of 120,000 square meters, with a total investment of 450 million yuan, and a designed annual output of 140,000 tons of aluminum profiles. After years of accumulation, Junmei Aluminum has equipped various automatic production equipment with a full industrial chain processing technology, including electrolytic aluminum, mold processing, extrusion, oxidation, powder spraying, fluorocarbon spraying, deep processing and welding. There are currently 18 extrusion production lines, one horizontal spraying line and one vertical spraying line, three wood grain transfer production lines, two oxidation production lines, four heat insulation strip production lines, five deep processing production lines, and three fine processing production lines.

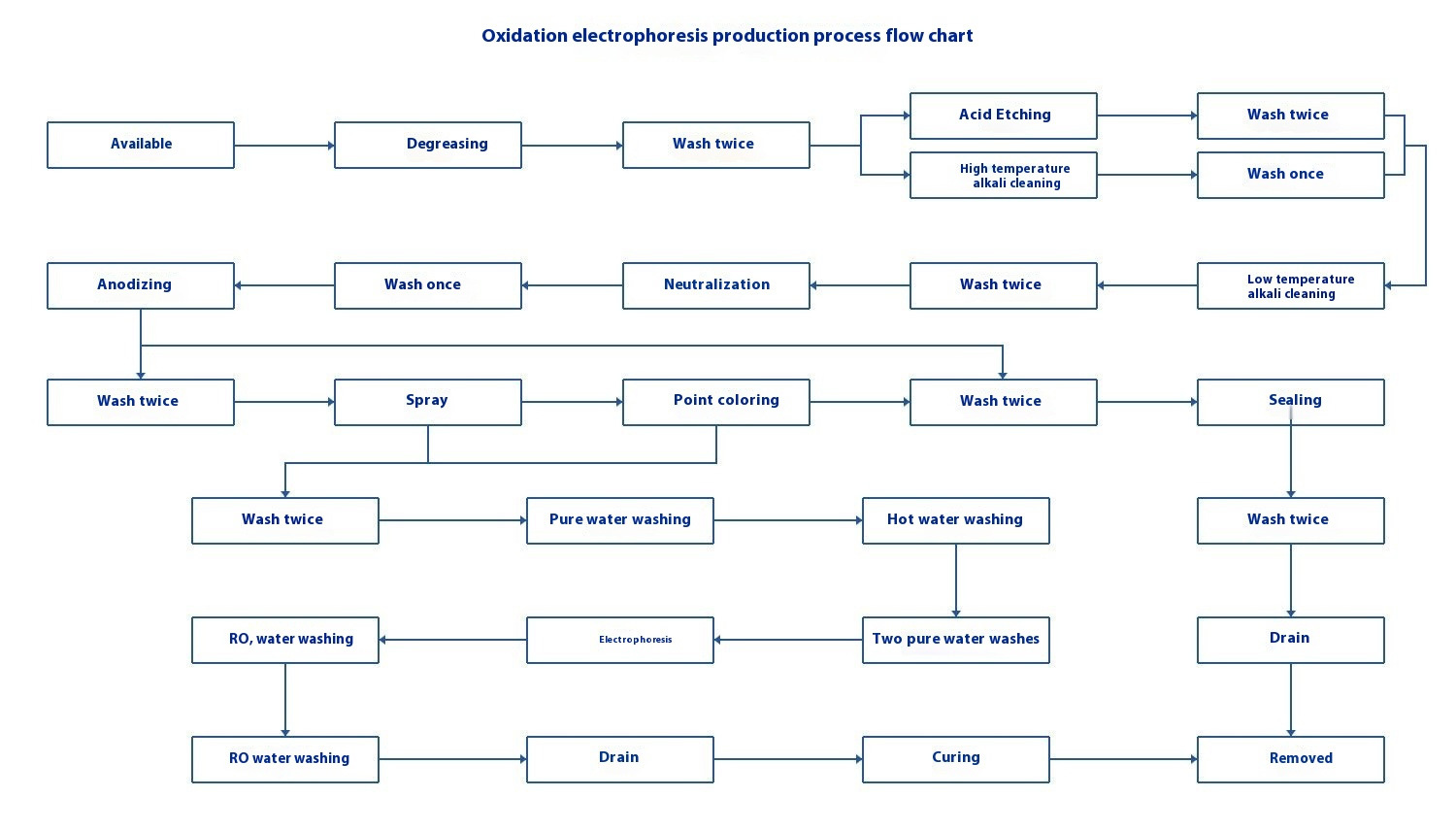

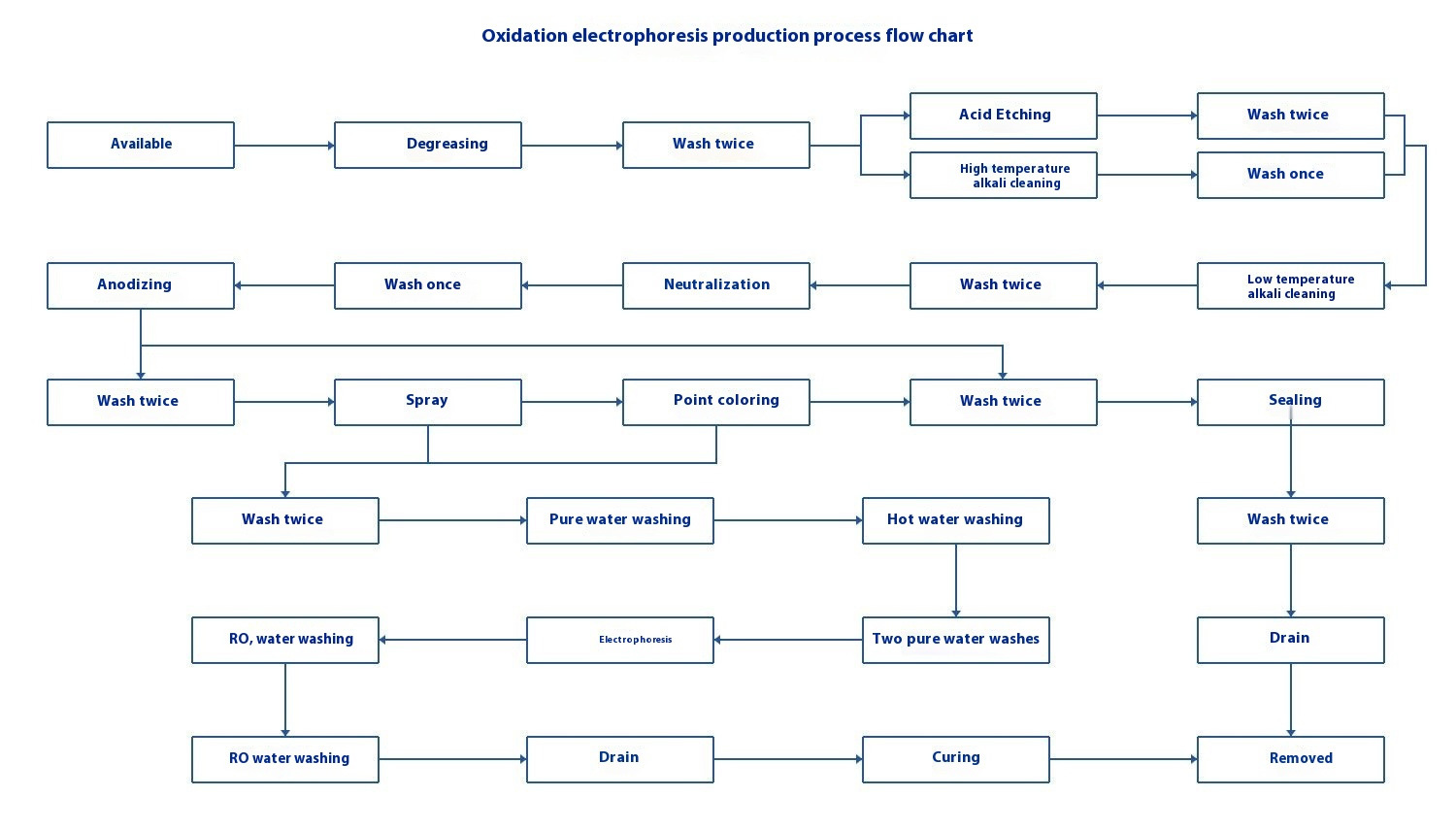

It can produce more than 100 series and more than 14,000 specifications of products such as anodic oxidation coloring, electrophoretic coating, powder spraying, fluorocarbon spraying, wood grain transfer, and steel ball blasting, maximizing customer needs.

It can produce more than 100 series and more than 14,000 specifications of products such as anodic oxidation coloring, electrophoretic coating, powder spraying, fluorocarbon spraying, wood grain transfer, and steel ball blasting, maximizing customer needs.

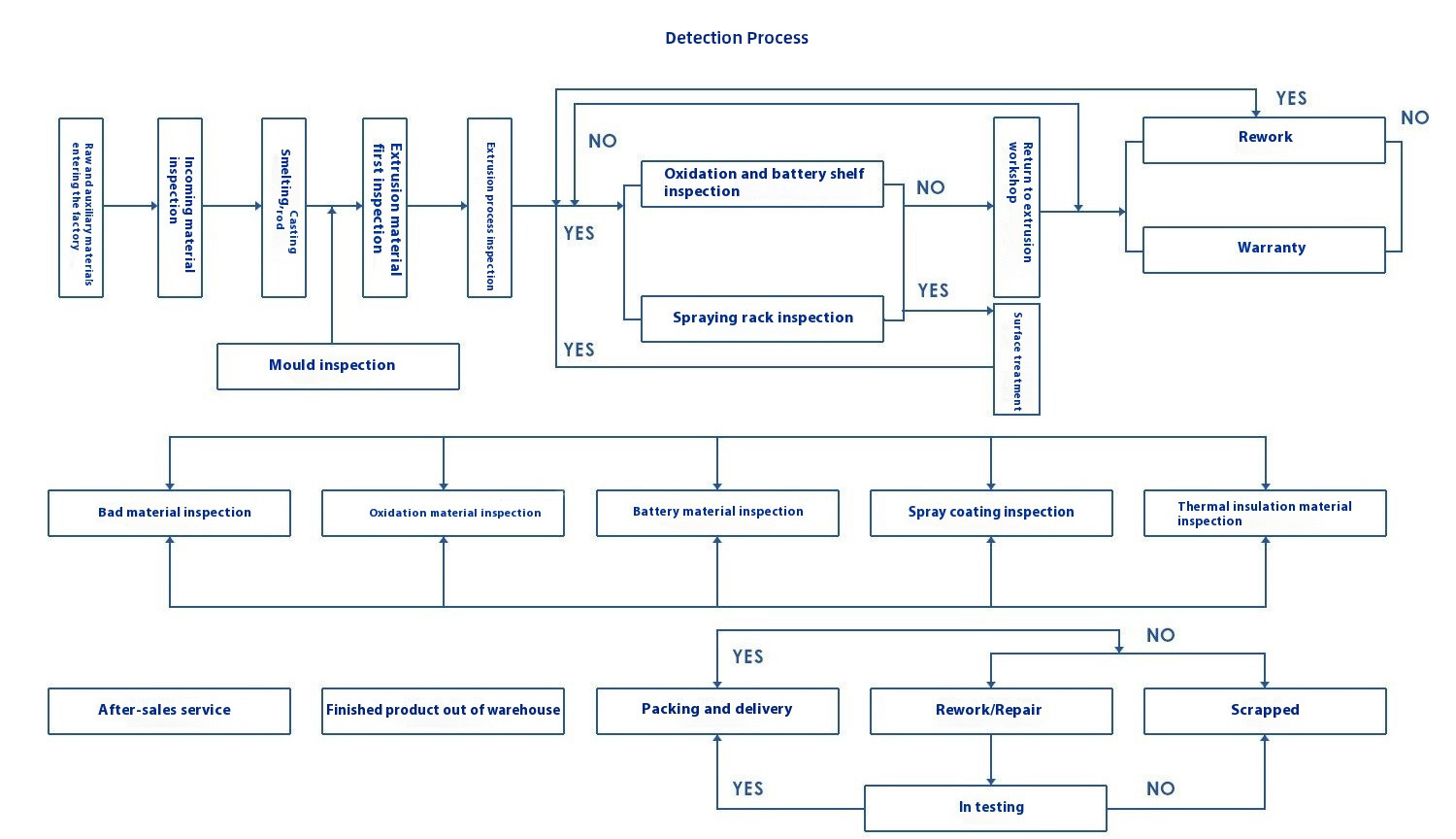

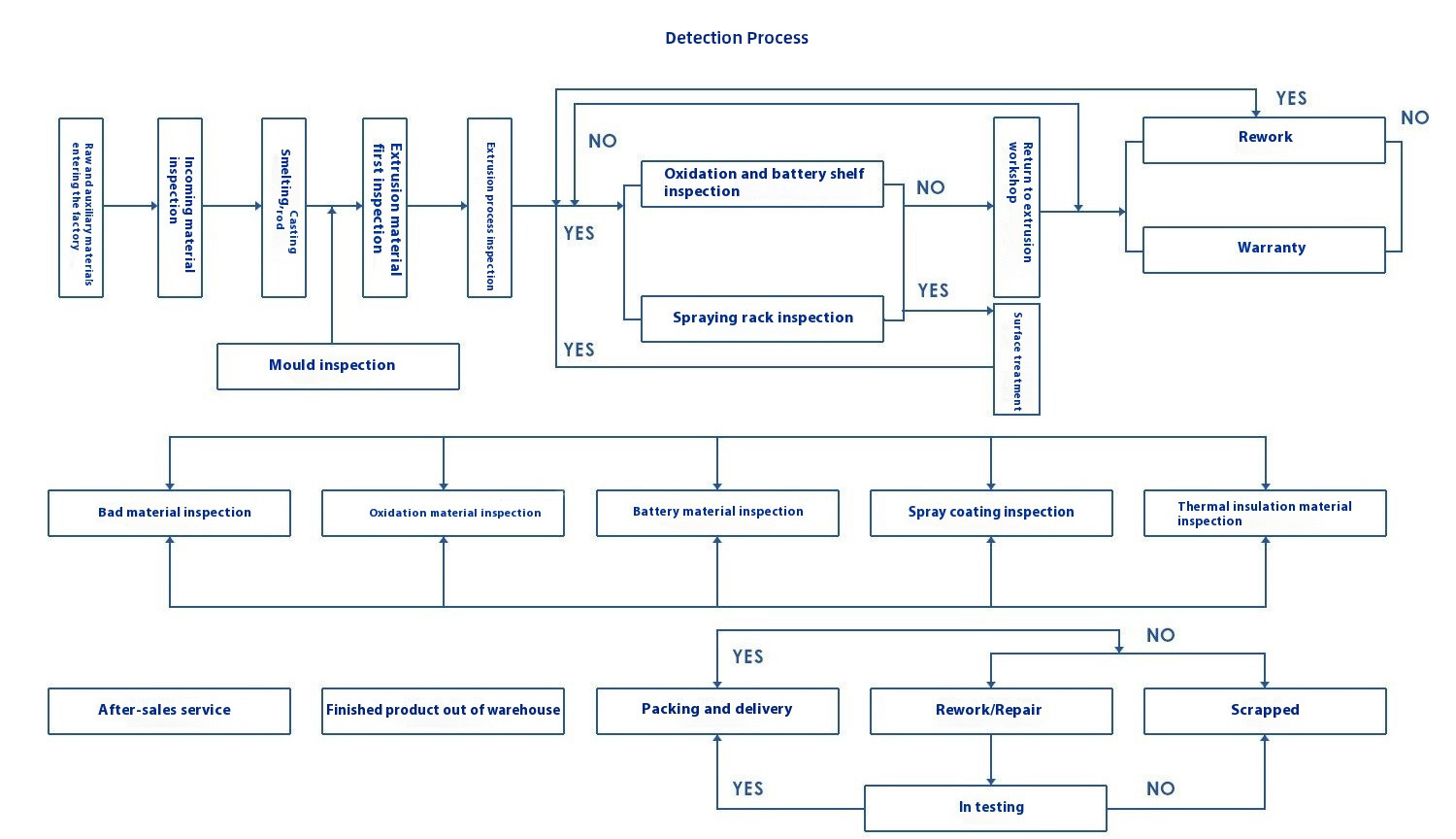

Junmei Aluminum has passed the ISO9001 quality management system certification, ISO45001 occupational health and safety management system certification, and ISO14001 environmental management system certification.

With high starting point, high standard, and high quality, Junmei people will continue to adhere to the principle of basing ourselves in Henan, radiating surrounding areas, facing the country, and looking at the world. We will use high-quality products and services to repay the society, benefit mankind, and sincerely cooperate with domestic and foreign colleagues to work together to create a green and low-carbon life.